Haitian Zhisheng Die-Casting Attends 19th China International Die Casting Congress

2024-03-27

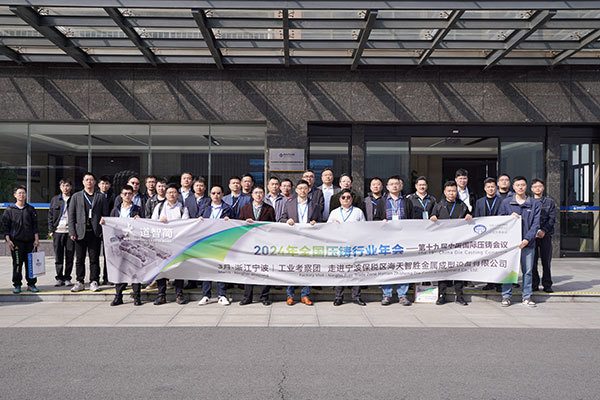

From March 21st to 22nd, the 19th China International Die Casting Congress, the annual national die casting industry meeting of 2024, was held at the Shangri-La Hotel in Ningbo. Leveraging Ningbo’s die casting industry cluster advantages, the conference, with the philosophy of “embracing simplicity of intelligence”, jointly explored more possibilities for innovation and optimization in integrated die casting processes with peers in the industry.

Haitian Die Casting (Haitian Zhisheng) deeply participated in and shared the forefront technical solutions for integrated die casting and thixomolding. With its outstanding innovative strength, Haitian Die Casting boosted industry reform. After the conference, pioneering integrated die casting mold-testing center and thixomolding mold-testing center were both opened for on-site visits to the guests.

The annual meeting focused on hot topics in the industry, including the development of new materials, design and process design of automotive OEM products, and sharing technical and management experience from die casting listed companies. The content covered the entire die casting industry chain, including design, materials, molds, equipment, production, and end-users, gathering OEMs, die casting foundries, universities, research institutions, and well-known suppliers with more than 700 representatives in attendance.

Mr. Zhou Lianjun, a senior application specialist, delivered keynote speech at the conference, comprehensively demonstrating Haitian Die Casting’s cutting-edge technical strength in the field of integrated die casting and thixomolding. Haitian Die Casting spared no expense in building the world’s first mold testing centers of integrated die casting and thixomolding, providing an important platform for mold testing and small-batch production, which undoubtedly vitalized the entire industry’s innovative development.

In his speech, Mr. Zhou particularly emphasized one of Haitian Die Casting’s core technologies, that is the RTC dual closed-loop real-time control injection technology. This technology boasts excellent real-time control performance, with a response cycle of merely 0.25 milliseconds, thereby ensuring high stability in the production process and a significant improvement of product quality.

Furthermore, Mr. Zhou also shared in-depth Haitian Die Casting’s continuous technical innovations and rich solution experiences in the field of integrated die casting and thixomolding. Based on these accumulated strengths, Haitian Die Casting can provide customers with customized, highly competitive, and technically advanced one-stop die casting clusters and production solutions, contributing significantly to the progress and development of the industry.

After the conference, Haitian Die Casting invited the guests to visit their advanced integrated die casting and thixomolding mold testing base, metal-processing area, assembly area for super-large die casting machines, as well as Haitian headquarters for on-site visits, allowing the guests to personally experience the charm and strength of Haitian manufacturing. This initiative not only deepened the attendees’ understanding of Haitian Die Casting’s technical strength but built a valuable platform for industry communication and cooperation.

In 2024, facing the new situation and new phase of the die casting industry, Haitian Die Casting adheres to the principles of technology leadership, reliable quality, and efficient service. It insists on technological innovation and win-win cooperation, grips industry trends, and strives for continuous innovation and breakthroughs in large die casting and thixomolding. It boosts the advances of lightweight vehicles in terms of aluminum and magnesium, and realization of energy-saving and emission-reduction goal.