Innovation to Help the Development of Large Die Casting | Haitian Die Casting Attended the 2023 Annual Congress for National Die Casting

2023-03-27

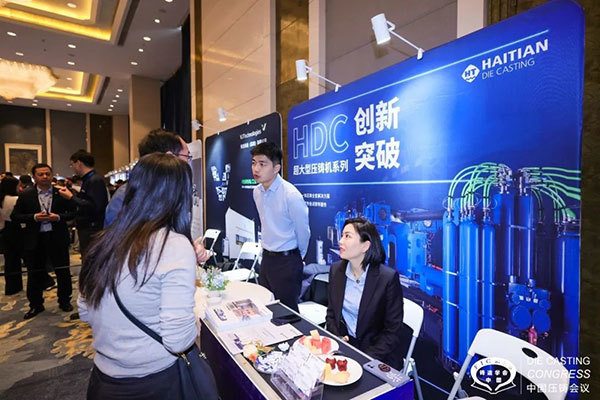

From March 22 to 24, the “2023 Annual Congress for National Die Casting” was successfully held at Shangri-La Hotel, Hefei. The congress focused on the theme of “New Energy Vehicle Manufacturing Leads the Era of Large Die Casting” to help the high-quality development of new energy vehicles. Haitian Die Casting brought the super large integrated die-casting solution and the newly launched 3,000T magnesium alloy injection molding solution to this forum.

The congress is sponsored by Chinese Mechanical Engineering Society, World Foundry Organization (WFO) Die Casting Committee and Foundry Productivity Promotion Center, and organized by Foundry Institution of Chinese Mechanical Engineering Society, National Key Laboratory of High-end Equipment Casting Technology, Shenyang Research Institute of Foundry Co., Ltd. CAM, and Public Service Platform for Industrialization of Innovation Achievements in Casting of Key Components in Equipment Manufacturing Industry.

More than 800 professionals from automotive, die-casting and other industries attended the congress to co-witness the new development of the die casting industry through keynote technical speeches and featured product exchanges.

Focus on new energy vehicles-Haitian Die Casting’s integrated die casting solution

During the congress, Mr. Zhou Lianjun, Senior Application Expert of Haitian Die Casting, made the report themed by Thinking and Solution of Integrated Die Casting on site about the insight of integrated die casting market. With the promotion of automotive lightweight and especially the huge potential for increasing the amount of aluminum used in domestic single vehicles, integrated die casting is gradually becoming a rigid demand for automotive companies.

Facing the market demand, Haitian Die Casting officially launched HDC8800T super large intelligent die casting machine in 2021, which has the leading double closed-loop full real-time control die injection technology, high-efficiency and powerful three-die clamping technology and intelligent KEBA control system.

In addition to providing high-quality die casting machine products, Haitian Die Casting has invested more than RMB 100 million to effectively help the development of the industry and fill the gap in the integrated upstream and downstream industrial chain, and equipped a set of 8800T super large mold testing unit in the Global Application Center. Since its operation in September last year, Haitian Die Casting’s 8800T mold trial unit has provided many domestic and foreign enterprises with mold trial and application testing services for new materials, new processes and new products, including automobile front cabin, rear floor, etc.

Mr. Zhou Lianjun said that Haitian Die Casting can provide super large die casting machines, integrated complete molding solutions and integrated mold trial services in the field of integrated die casting and also introduced Haitian Precision’s special machining solutions for integrated die casting.

Facilitate lightweight magnesium alloy applications-Haitian Die Casting’s magnesium alloy injection molding solution

In recent years, with the proposal of carbon peaking and carbon neutrality goals, lightweight has been developed and applied rapidly in the field of new energy vehicles. For example, car screens are moving towards dual, triple, and large-sized screens. In order to solve the production problems of such large-sized and high-demand die castings, as well as ensure the safety and environmental protection of magnesium alloy production, Haitian Die Casting has launched a large magnesium alloy injection molding machine HMG3000 with advanced full real-time control injection technology, which has a locking force of over 30000 kN, a screw diameter of 150mm, and a theoretical injection volume of up to 10kg for magnesium alloy, providing an excellent choice for the production and application of large-sized magnesium alloy materials such as multi screen backboards, seat frames, and interior door panels.

Haitian Die Casting will continue to increase the investment in R&D and supporting services while adhering to the technological innovation to accelerate the development of large die casting and provide customers with high-quality special solutions on aluminum and magnesium alloys to meet the differentiated needs of the market and effectively promote the development of lightweight.