One-stop Die Casting Solution

With the development of the market application of aluminum magnesium alloy die casting, especially in industries such as the automotive lightweight structural parts, new energy vehicle battery pack and 5G communication, there are more and more highly integrated large-size products and high-demand die castings, and the market demand for ultra-large and ultra-precision die casting machines is also increasing. Therefore, Haitian Die Casting has established a global application center, covering an area of 5000 square meters and equipped with 2500T and 3500T double closed-loop real-time control die casting machines, aluminum alloy quantitative furnace,

high vacuum equipment, full mold temperature detection and control systems, robot peripheral automation, high-end spray systems, and “X light detection room”, to provide product testing and functionality testing, conduct application testing on new materials, new processes and new technology for global high-end customers and mold factories Meanwhile, Ha巾an Die Casting will build a high-end application team to provide customers with a series of application support services from equipment selection, a full set of molding solutions, mold guidance, die casting process and production guidance.

Quick Check

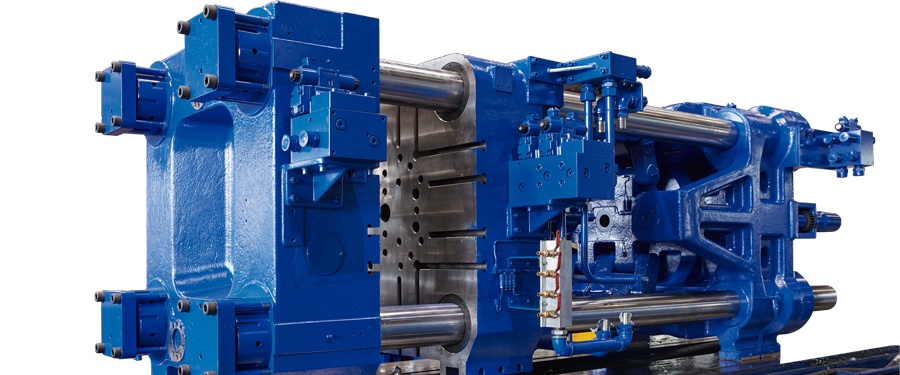

Shot unit:

dual closed-loop real-time control

Drive technology:

Servo-drive

Clamping force:

1.800 – 88.000 kN

Clamp system:

5-point toggle structure

Max. tie bar distance:

2500 x 2500 mm

Shot volume (aluminum):

0.8 – 380 kg

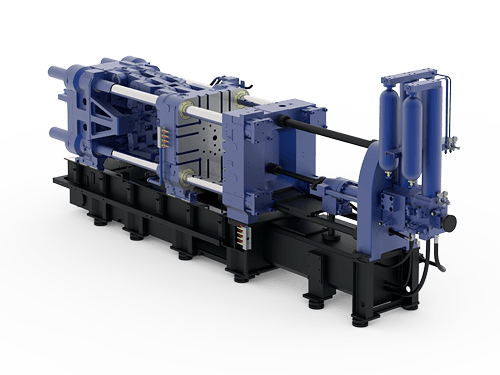

Discover Haitian HDC Series (180T-850T)

blanc

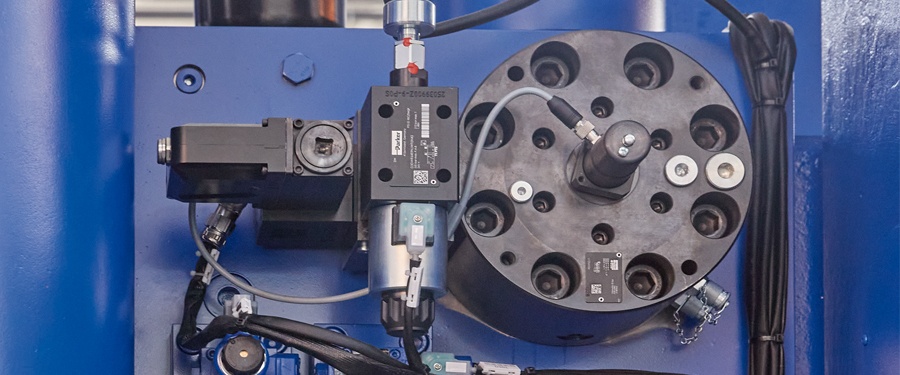

Dual closed-loop real-time control injection system (optional)

-1.jpg)

It is equipped with fast meter-in servo valve + fast meter-out servo valve + intensification meter-out servo valve to realize dual closedloop control of pressure and speed.

Semi closed-loop injection system (optional)

.jpg)

It is equipped with electric control valve + injection curve to realize the automatic adjustment of 1 st phase,2 nd phase and intensification speed, and realize automatic correction; at the same time, it can display the pressure, speed, position and other curves, and record the injection data.

Customized 2 nd phase valve

The fast response valve specially developed for the speed II acceleration performance of the die casting machine has faster, more stable and more durable injection speed.

Thickened enterprise board

The thickened enterprise board and the thick pull rod are conducive to maintaining the coaxial degree of injection for a long time.

Automatic pressure relief of accumulator

Equipped with quick/boost accumulator unloading valve, it can realize automatic pressure relief of shutdown accumulator with high safety.

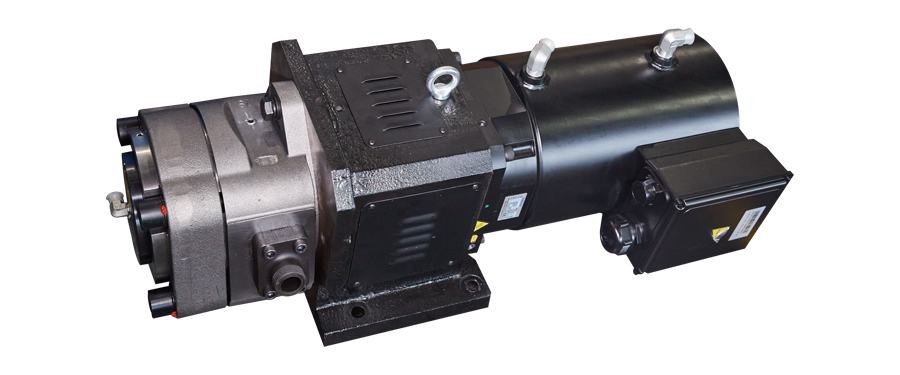

High performance servo system

The high performance servo system of Haitian is adopted to save energy significantly, and the oil cooling mode with high efficiency and stability is configured. (servo)

Intelligent Keba computer control system

Equipped with the mold locking force display (servo), injection curve and intelligent quality online function of the whole machine, it has a 12 Inch Touch screen with powerful function, stable performance, good expansibility and long service life.

Two-in-one independent electric box

The main control electric box and servo electric box are combined into one, realizing the integral hoisting. After installation, it is separated from the frame without vibration interference.

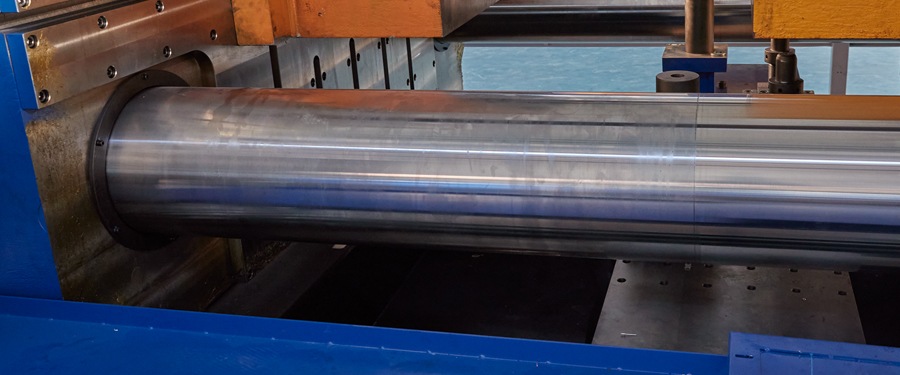

Special tie bar

The tie bar is made of special materials developed by the Haitian Materials Research Institute, with an enlarged diameter, good stress and strong rigidity. After years of practical use, it can significantly extend the service life of the pull rod.

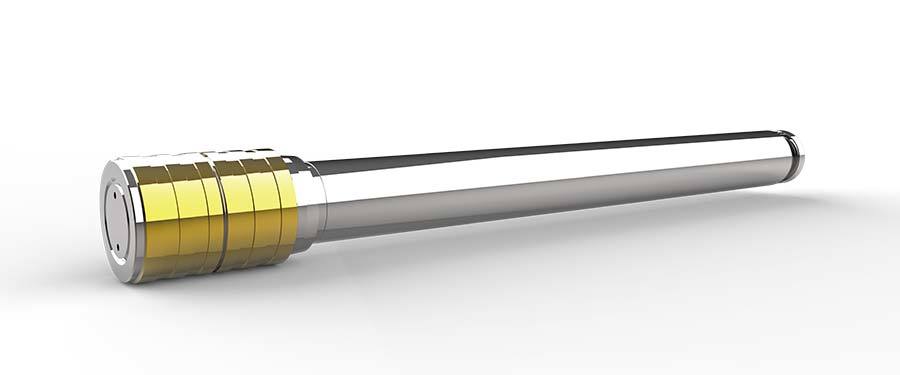

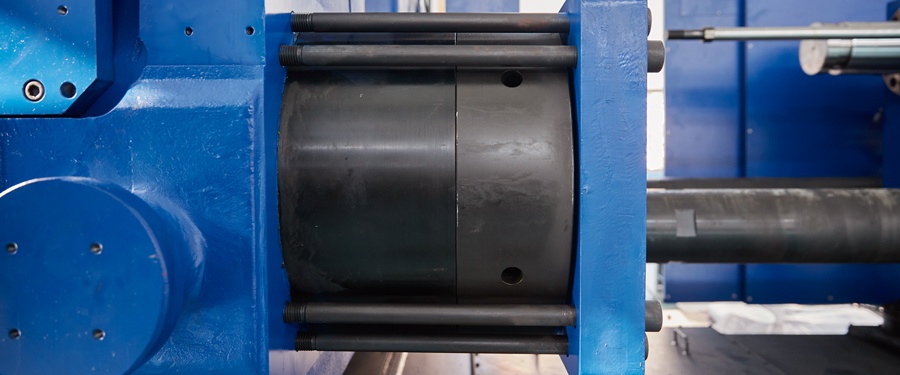

High-performance lock shaft

The lock shaft is made of 38CrMoAl material and is nitridated, with a large diameter, high strength, good toughness and long service life.

Adjustment nut

The adjustment nut is made of inner pouring aluminum bronze, which has higher mechanical properties, wear resistance, corrosion resistance, cold resistance, heat resistance and no ferromagnetism; it has good antifriction, good elongation and long service life; it can ensure smooth mold adjustment, effectively prevent mold adjustment from not moving, and protect pull rod thread.

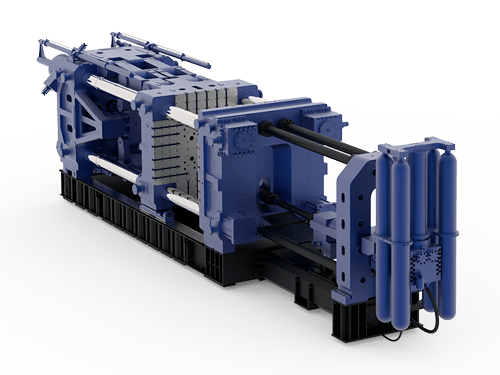

Thickened three platens

Thickened three platens have high strength, good wear resistance and small deformation.

Stiffener structure of middle plate

The structure of supporting rib plate is added to the middle plate, which effectively reduces the deformation of the middle plate, and fixes the ejector cylinder on the rib plate, which solves the problems of ejector cylinder swing, uneven ejector force, broken ejector pin, broken ejector cylinder piston rod, etc.

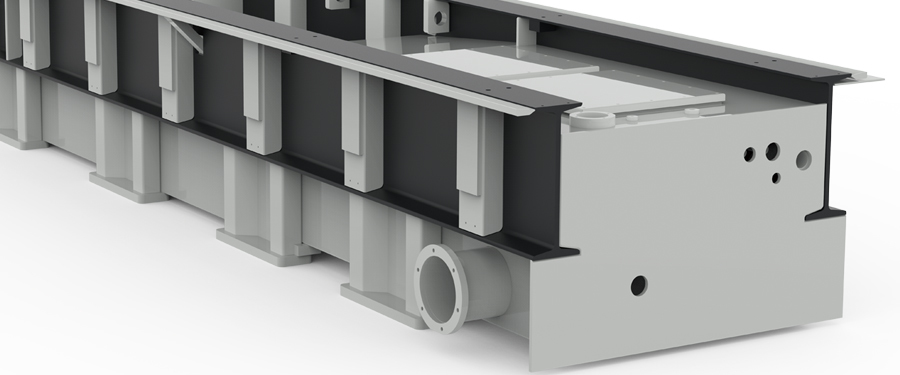

Machine base design

The frame is of high-strength I-beam structure. The center line of the sliding foot of the formwork and the center line of the upper and lower tie bars are in the same plane with the I-beam support bar. After annealing treatment, the anti-twisting ability and rigidity of the frame are greatly enhanced, which ensures the overall accuracy of the machine for a long time.

Mold closing motion analysis

Through the analysis of Haitian’s unique hinge motion software, the five-point mechanical structure is optimized and advanced slope control mode is adopted to make the energy output curve of the pump station system, the motion curve of the mold locking cylinder and the motion curve of the mechanical hinge be almost perfectly matched; within the range of the mold opening stroke, the middle plate can stop at any position within the opening stroke and with high repetition accuracy, effectively shortening the production cycle.

Intelligent mold adjustment structure

Equipped with automatic mold adjustment function, the hinge can be extended to adjust the mold. The mold adjustment motor is equipped with a self-locking function, which effectively solves the problem of the reduction of the clamping force caused by the retreat of the mold closing mechanism, and better guarantees the stability of the product.

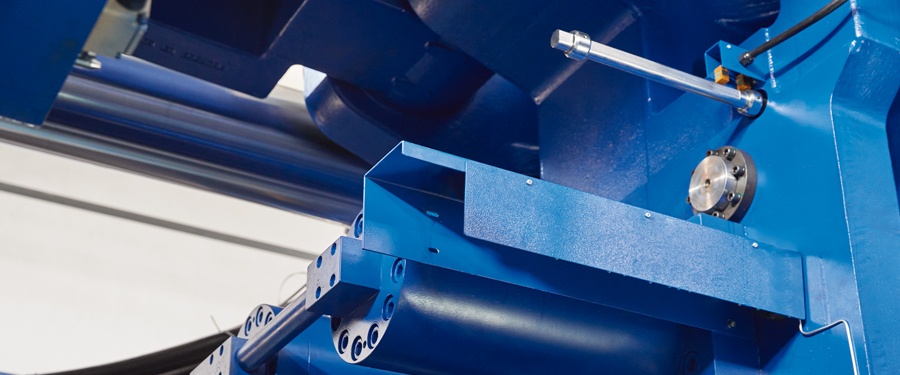

Extended guide sleeve structure

The extended guide sleeve structure of middle plate can ensure more smooth and reliable operation of middle plate.

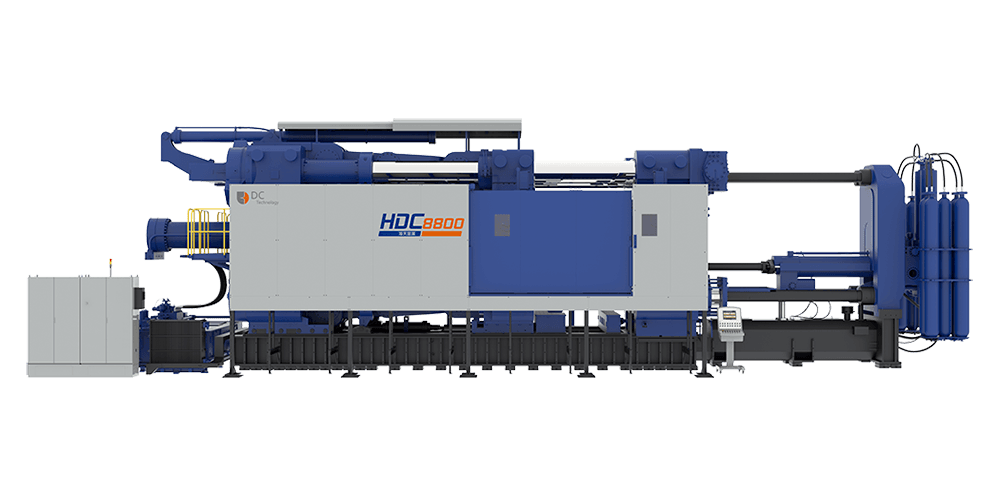

Discover Haitian HDC Series (1000T-8800T)

blanc

Dual closed-loop full real-time control system

It is equipped with fast inlet servo valve + fast outlet servo valve + booster outlet servo valve to realize fast dual closed loop control of pressure.

High system pressure

The pressure of the system can reach 190bar-210bar, the reaction speed of the whole machine is faster and the performance is better.

Large material cylinder piston

The exclusive rigid welding structure can reduce the friction resistance in the process of movement, reduce energy loss, effectively avoid the internal leakage caused by the pulling of the injection cylinder and prolong the service life of the seal.

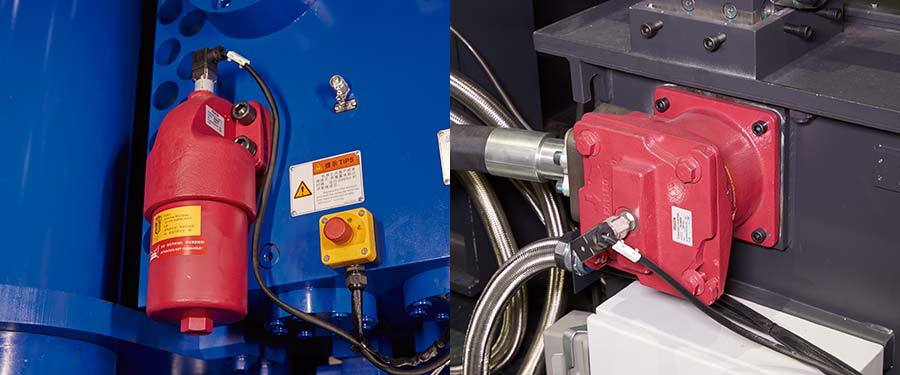

Multiple hydraulic oil filtration

Equipped with oil suction filter, outlet high-pressure filter, bypass filter, core-pulling oil return filter, injection servo filter, etc., it can greatly improve the protection of hydraulic oil cleanliness and ensure the reliable work and service life of hydraulic components.

Detection and control of hydraulic oil

Equipped with multiple oil temperature and oil level display and alarm, and equipped with automatic oil temperature preheating function and independent pump active water cooling system, oil temperature control is more reliable.

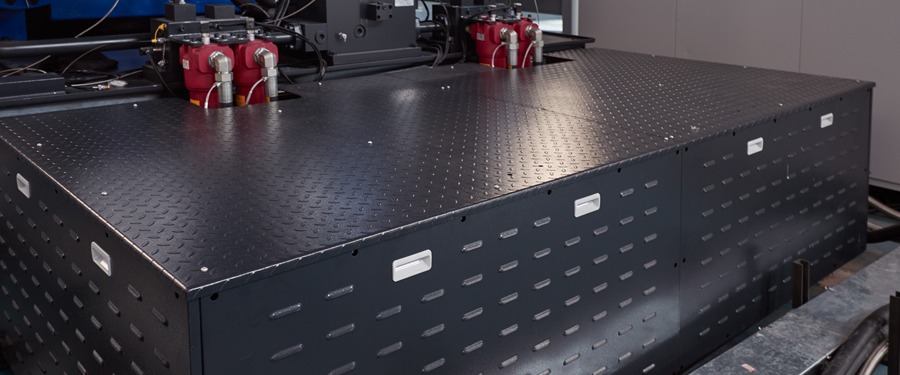

Design of independent oil tank

The independent oil tank structure and paint baking process are more favorable to the hydraulic system, and the oil change and maintenance are more convenient.

Substation mode

The industry’s first to use the mode of substation mode (IO distributed), which is more stable and anti-interference; multiple CPU partitions are independently controlled and the circuit is simplified, making the signal transmission faster.

High performance servo system

Adopting Haitian high performance servo system with remarkable energy saving and configured with efficient and stable oil cooling method.

Upgraded tie bar material

CL516, which is newly developed by Haitian Materials Research Institute, has higher strength and better toughness.

Auxiliary template

The mold surface of the movable and fixed plate is equipped with P20 mold steel (auxiliary template), whichcompletely solves the long-term problem of mold surface depression in the industry, and also improves the rigidity of the template.

Hydraulic pulling rod

Hydraulic pulling rod is above the operation side; the installation position of the hydraulic pulling rod above the non-operation side is reserved for self-selection.

Over stress protection mechanism

The special over stress protection mechanism is adopted for the head plate tie bar nut, which can effectively protect the pull rod and significantly prolong the service life in case of unbalanced force on the mold.

Mold opening and closing control

The large flow proportional valve is used to control mold opening and closing, making the mold opening and closing reaction faster and the position more accurate. At the same time, the clamping hydraulic safety valve is configured, making the clamping safety protection more reliable.

Ejection structure

The ejection rod position is controlled by MTS magnetic scale+ limit switch , double configuration for convenient switching.

High-strength body

Exclusive use of I-beam or H-beam structure frame, and the overall annealing stress relief, good force, rigidity, good resistance to deformation.

Multiple security facilities

It is equipped with safety module, front door safety grating, rear door electric eye, life safety lock, lock mode confirmation, machine hinge grating protection, multiple emergency stop switches, so that the operation safety is more guaranteed.