Haitian Magnesium Injection Technology Debuts in Chongqing, Driving Lightweight Solutions for Low-Altitude Aviation and Robotics

2025-04-12

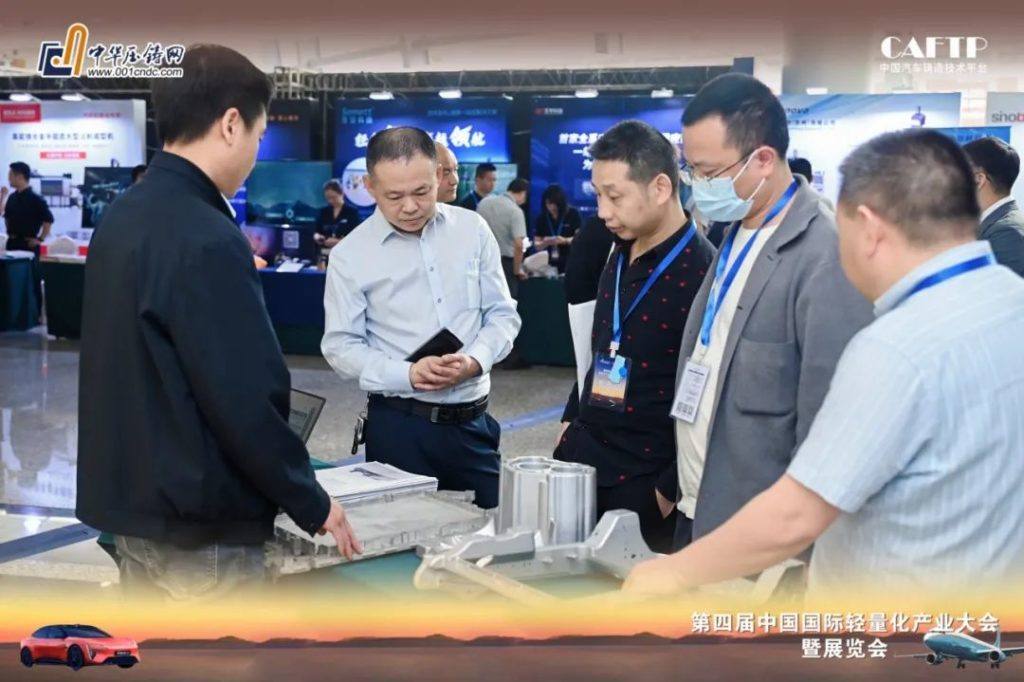

On April 11, the 4th China International Lightweight Industry Conference & Exhibition opened grandly at the Chongqing International Conference and Exhibition Center. As a leading enterprise in lightweight metal forming and equipment manufacturing technologies, Haitian Zhisheng Die-Casting was invited to attend. Senior Application Manager Fu Bangyin delivered a keynote speech titled “Development and Application of Large Magnesium Alloy Injection Molding at Haitian Zhisheng Die-Casting,” where he shared the company’s innovations in magnesium alloy injection molding technology and its market application cases, drawing wide attention from the industry.

As the lightest structural metal material, magnesium alloy offers high specific strength, excellent vibration damping, good thermal conductivity, and recyclability. It holds broad application prospects in new energy vehicles, two-wheelers, 3C electronics, robotics, and the emerging low-altitude economy. With the growing global demand for energy conservation and emissions reduction, the magnesium alloy market is entering a period of rapid expansion.

Fu Bangyin noted that Haitian’s HMG series magnesium alloy injection molding machines combine a high-rigidity, flexible clamping structure with a redesigned hydraulic system tailored for high-precision, high-performance molding. Equipped with advanced technologies such as a servo energy-saving drive system, the HMG series delivers an unprecedented magnesium alloy molding experience for users.

In his presentation, Fu Bangyin placed special emphasis on the application potential of magnesium alloys in emerging fields such as the low-altitude economy (including drones and eVTOL aircraft) and humanoid robotics. The lightweight characteristics of magnesium alloys can significantly enhance the endurance and payload efficiency of aircraft, making them ideal for critical components such as drone fuselages and aerospace structures. Meanwhile, in service robots, robotic dogs, and humanoid robots, magnesium alloys help reduce the weight of moving parts, improving flexibility and energy efficiency, and driving the robotics industry toward becoming lighter, stronger, and smarter.

In addition, Haitian Zhisheng Die-Casting has successfully delivered magnesium alloy forming solutions to several leading enterprises, covering applications such as automotive lightweight components and consumer electronics housings, fully demonstrating the maturity of its technology and its strong market competitiveness.

As global manufacturing continues to advance toward green, efficient, and intelligent development, aluminum and magnesium alloys—as key lightweight materials—will play an increasingly important role in more high-end sectors. Seizing this momentum, Haitian Zhisheng Die-Casting will continue to deepen technological innovation and work hand in hand with industry partners to drive the wider application of aluminum and magnesium forming, injecting new vitality into the growth of the global lightweight industry.