Premiere of the probably largest Magnesium injection molding machine worldwide

2023-05-18

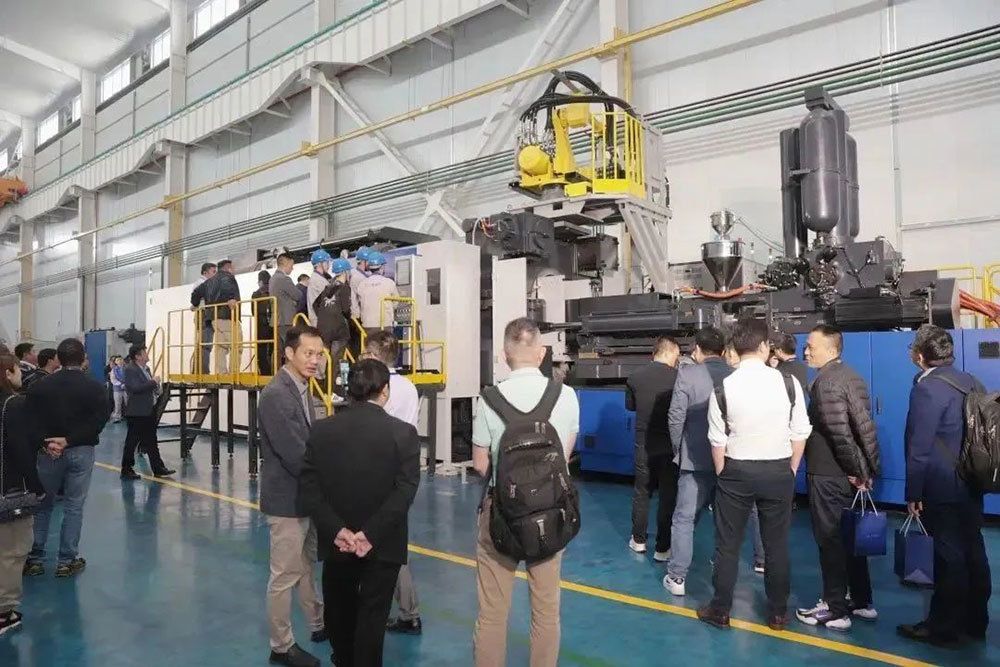

Haitian Die Casting is breaking the limits for Thixomolding machines, also known as magnesium injection molding. The HMG Series is now available with clamping force classes of up to 3,000 tons, making it the largest thixomolding machine currently on the market. The new HMG3000 was officially introduced to customers, partners and the press on May 12, 2023 at Haitian Die Casting’s manufacturing plant in Ningbo, Beilun.

Magnesium applications gaining in importance

Thixomolding is an injection molding process in which a magnesium alloy can be processed into complex molded parts in a semi-solid state. The material is of low density and weight, but at the same time enables very high rigidity and strength in construction. It is ideal for all applications where weight savings are important, such as in aerospace, vehicle construction or the manufacture of sports equipment.

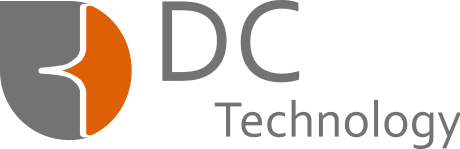

Driven by joint development and independent innovation, Haitian Die Casting has successfully developed the world’s largest 3,000-ton magnesium thixomolding machine HMG3000. At the beginning of the launching ceremony, Mr. Ge Qiwei, the project leader of thixomolding machine from Haitian Die Casting, made an impressive presentation of the new product. The HMG3000 features clamping force up to 30,000kN, with maximum screw diameter up to 150mm and theoretical injection volume of more than 10kg and that it is equipped with advanced dual closed-loop full real-time control system. It thus provides an excellent solution for products such as the large-size multi-screen display back panel, seat frame and interior door panel made of magnesium alloy.

Mr. Ge Qiwei, General Manager of Haitian Die Casting Magnesium Alloy IPD

Speaking as a customer representative, Xu Cheng from Millison Technology expressed sincere congratulations on the launch of new magnesium alloy injection molding machine by Haitian Die Casting, and expressed that Millison Technology is willing to further deepen cooperation with Haitian Die Casting to jointly promote the lightweight development of the automotive industry.

Mr. Xu Cheng, Millison Technology

Mr. Qian Ming, Secretary-General of China Foundry Association Die Casting Branch delivered a speech, saying that the successful development of HMG3000 by Haitian Die Casting is the result of close cooperation between multiple forces, which will accelerate the application of magnesium alloy in automotive lightweighting and make a new contribution to China’s carbon peaking and carbon neutrality strategy.

Mr. Qian Ming, Secretary-General of China Foundry Association Die Casting Branch

Mr. Le Xiaodong, General Manager of Haitian Die Casting, said that Haitian Die Casting has been committed to the R&D and innovation of cold chamber die casting machines and thixomolding machines. The mass production of HMG3000 has broken the limits for the thixomolding in the market, and has achieved many breakthrough results. In the future, Haitian Die Casting will continue to strengthen our R&D power, while paying great attention to the product quality and service, and work with upstream and downstream partners to jointly promote the development of China’s die casting industry.

Mr. Le Xiaodong, General Manager of Haitian Die Casting

Later, 8 guests jointly launched the gilded sand to officially launch the HMG3000 thixomolding machine under the joint witness of the guests.

Learn from advanced experience, strengthen exchanges and promote common progress

During the technical seminar in the afternoon, the industry experts focused on cutting-edge technology and discussed the technical solutions from the fields of materials, equipment, molds, processes, etc., to devote to and draw a blueprint for the future development of the industry by taking magnesium alloy injection molding as the topic point.

Green technology with potential for the future

The processing of magnesium is sustainable and forward-looking for many industries, such as the automotive industry and e-mobility. Advantages over other materials include:

- Magnesium is extracted from natural minerals such as dolomite and magnesite, which are common on earth.

- Magnesium is 100% recyclable, can be melted down again and again without loss of quality.

- Magnesium alloys are biodegradable, can be decomposed in nature and do not pollute the environment.

The launch of HMG3000 thixomolding machine marks another milestone for the development of Haitian Die Casting. Haitian Die Casting will continue to increase investment in scientific research and supporting services, continuously improve the quality and performance of products, making continuous efforts for development of lightweight of automotive industry.